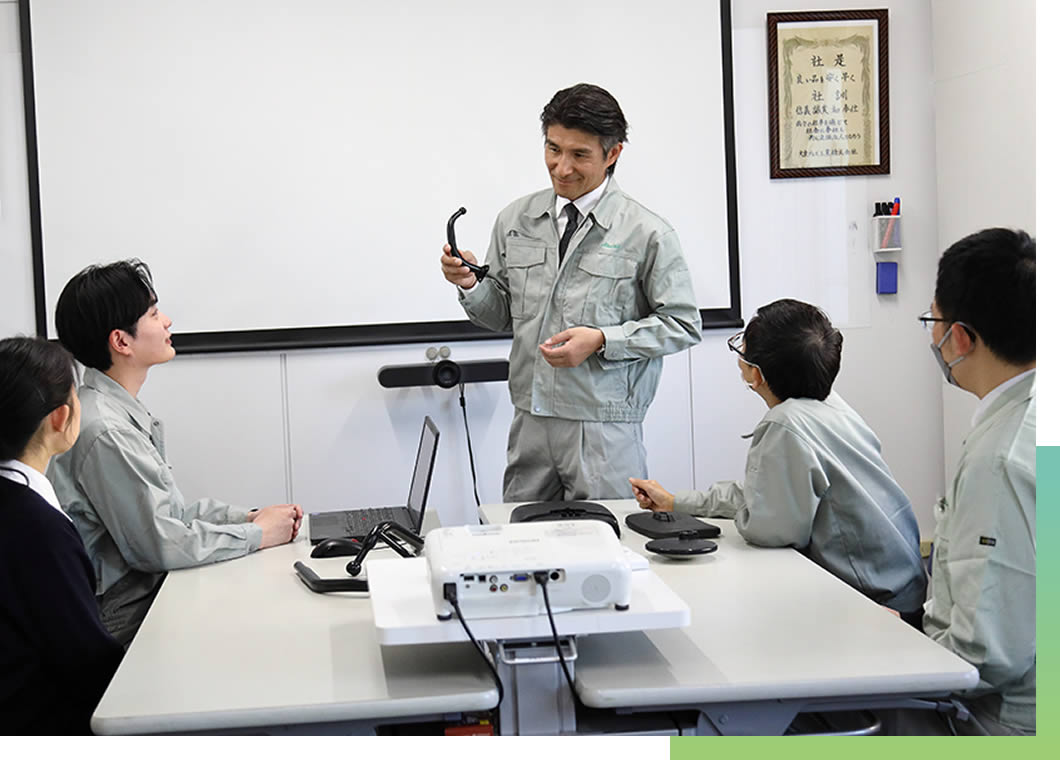

order made

First, we hear what the customer wants and set the product concept. Based on the concept, we determine the overall specification such as the size, materials, and expected performance.

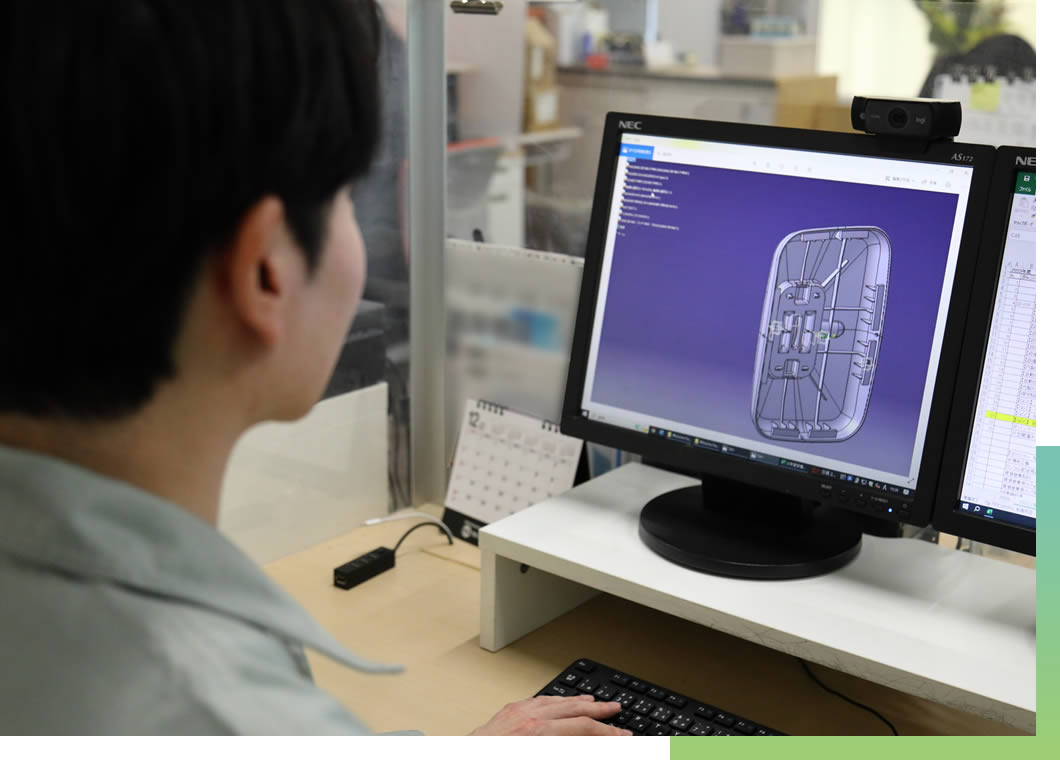

After the specification is set, we design the product exterior. With the product image of the actual installation, we proceed the product design with understanding customer’s needs.

Making prototype is available upon customer’s request. Customers can check the product design with prototypes.

With the specification and design, we develop the prototype with using CAE analysis.By developing towards the mass production from the stage of the prototypes, it leads to the product development with cost balanced.

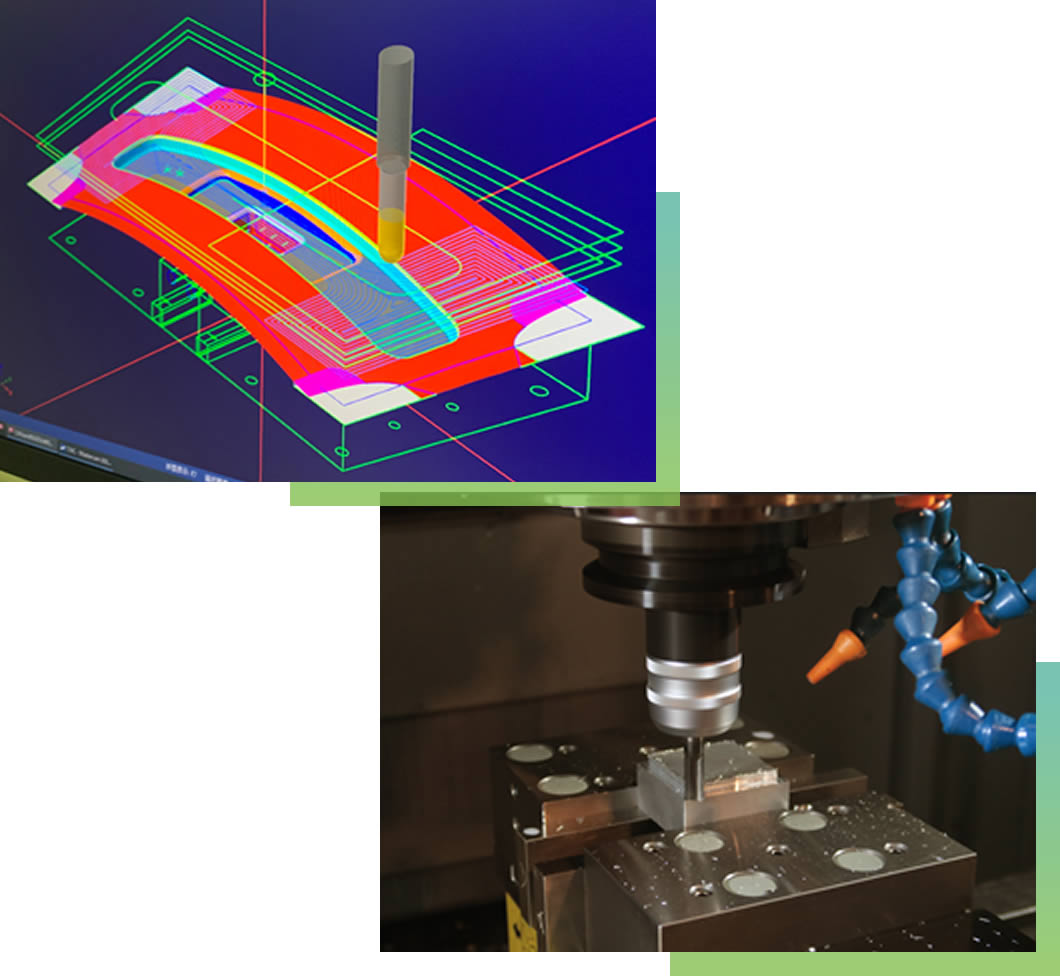

Based on the product drawing, we make a mold.

We can make a new mold as long as we have the actual product.

With a long time

experience, knowledge and well trained technique, we provide the products which meet

customer’s expectations.

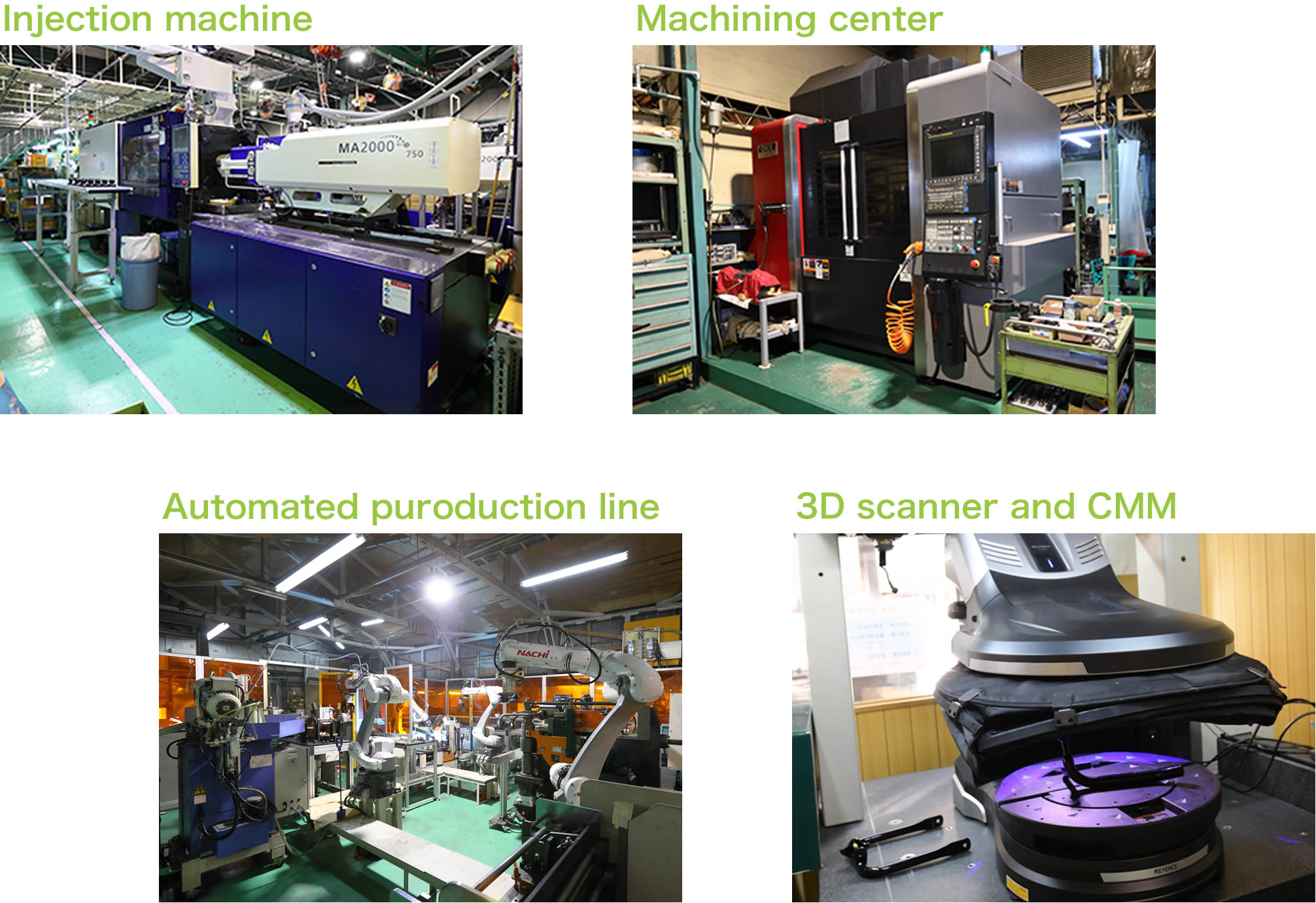

We use measuring instruments and inspection equipment, and check if the product meets the evaluation criteria assumed in the product design phase.

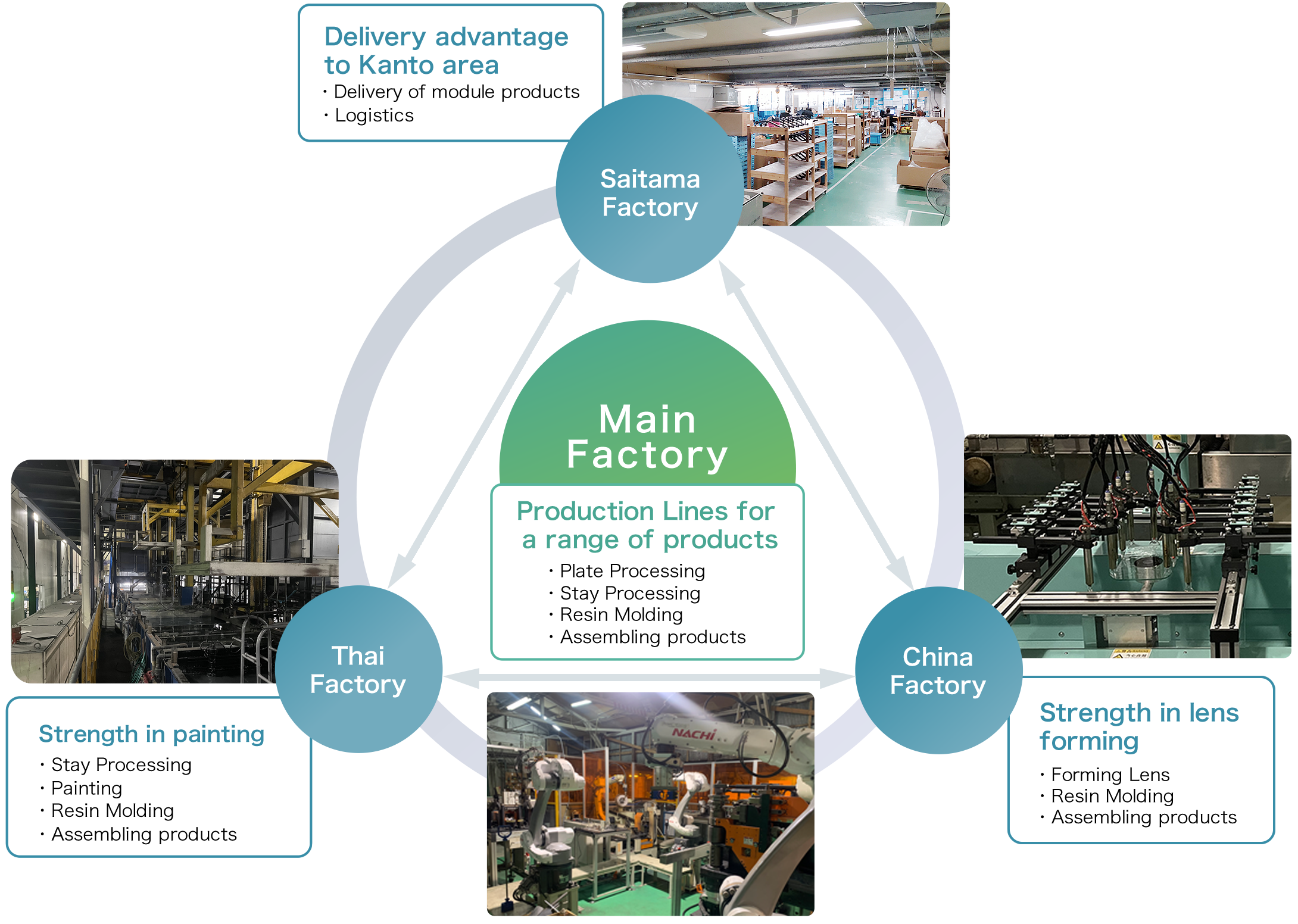

Products are manufactured in the own factory

and delivered to customers.

We ensure the follow up after the delivery. Please feel

free to contact us.